Fast > High production rate (few seconds)

Compact > Under 2m² / 22 ft² floor space

Efficient > Meets to cleanliness standards | ISO 16232 – VDA 19

Robot friendly > Robot cell cleaning

One piece flow cleaning process without buffer

Lean manufacturing solution

Made in France

MecanoFAST ensures a very high cleaning rate from 20 to 60 seconds depending on the workpiece type and complexity!

Designed to be easily integrated into the production flow, MecanoFAST allows easy integration between upstream and downstream manufacturing processes.

Under 2m² / 22 ft² floor space

Width 700mm / 2′ 3 9/16”

The batch/basket cleaning concept generates a major disruption for the production efficiency resulting in slowing down the flow and generated downstream and upstream stock.

The MecanoFAST process takes a very different approach , this equipment use the one-piece flow concept with a short cycle time.

Continuous flow: no batch

Loading and unloading on the same fixture

Single piece > no buffer

Quick detection of machine failure

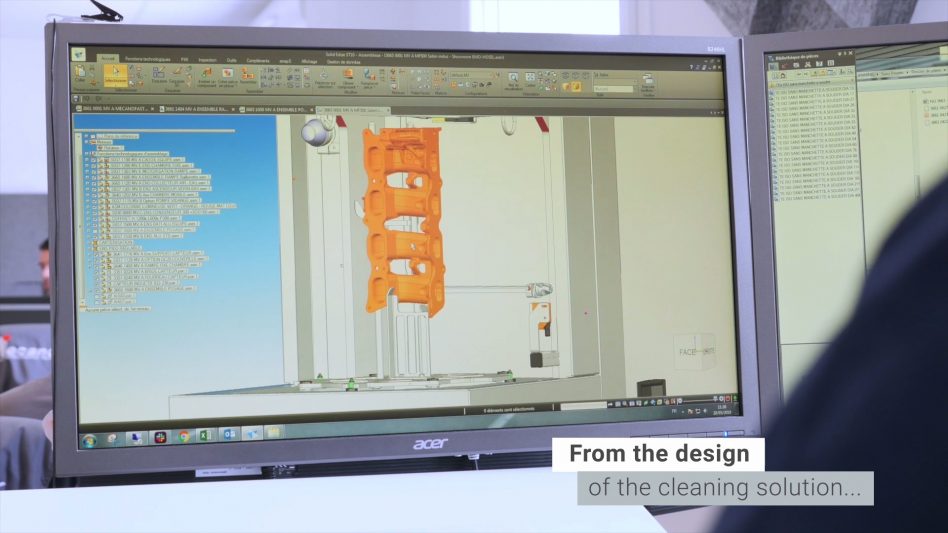

The part fixture, the cleaning/drying tools are designed in 3D model and produced according to the parts drawing.

Cleaning and drying of critical areas, blind holes, thread, etc…

Perfect drying

Part exit temperature below 35°C (95°F)

The MecanoFAST integrates high quality components from premium brands.

Display and process data monitoring

Automatic addition / topping up of detergent

Programmable partial drain

Overall the MecanoFAST system consumes 2 time less energy and around 4 times less water than the traditional Tunnel or Carrousel system type.

Is your assembly or production line operate manually or fully automated ?

The MecanoFAST system has a large front loading/unloading access for a quick and efficient load.

Quick change over > replace tooling in less than 5 minutes !

Reconfiguration > only the tooling need to be replaced to run a different part number.

Integration of an indexed rotary table ensuring loading/unloading in masked time during cleaning cycle.

Also allows the integration of additional post cleaning process such as marking, traceability, quality check etc…

We support you by setting up validation trials and analysis in our laboratory.

Gravimetry and particle size

Standards VDA19 – ISO 16232

Surface tension measurement

A roller shutter combined with a set of sensors to ensure a secured and simplified access to the filtration system, tank and other moving parts.

Self-cleaning of the work chamber

Automatic or complete partial draining

Maintenance monitoring management via HMI

Option to connect the machine to an outside central washing unit