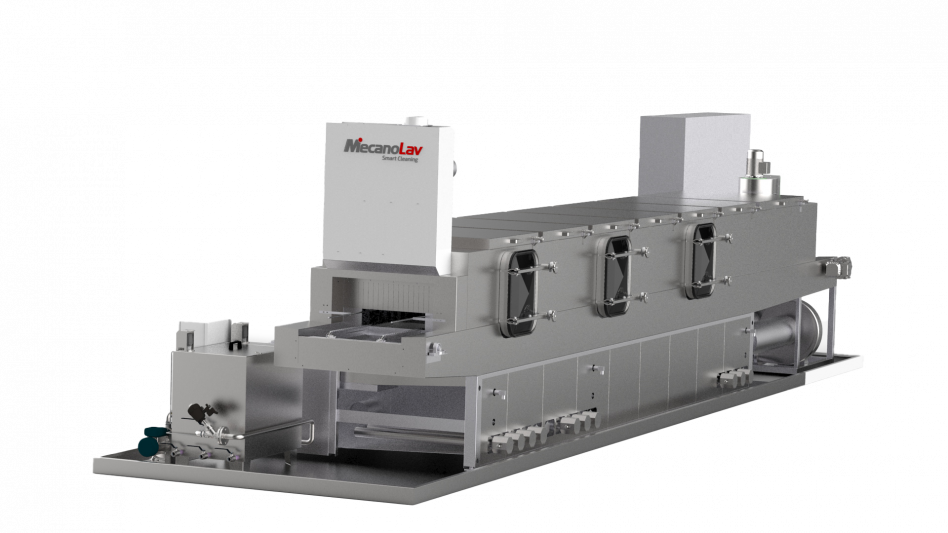

Modular design > lenght / lines / stages

Useful dimensions can be adapted as needed

3 conveying technologies : Chains – Belts – Workpiece carriers

High flow > 0,5 to 2 meter / minute

304L Stainless steel structure for strength and durability

Easy maintenance access to modules and tanks

Made in France

Well established in high rate production processes, the tunnel parts washer can be tailored to the application and allows the integration of multiple modules for continuous part processing.

Degreasing steps

Phosphation steps

Reverse flow rinsing steps

Passivation and rust protection steps

Hot air drying steps

For optimal cleaning and drying, the useful dimensions of the tunnel are adjusted to the shape and size of the parts to be treated.

Useful width from 100 to 9000 mm

Useful height from 7 to 1200 mm

Designed to handle multiple part references, especially in the general industry , the tunnel parts washer is made up of a stainless steel wire mesh belt to accommodate part diversity.

Driven by a geared motor with torque limiter

Adjustable guiding rails

Configurable speed

Two stainless steel chains with hollow links enable scrolling of existing Work Piece Carrier. A first conveyor upstream, a second one at the exit of the tunnel ensures the return of the carrier towards the next operation.

Input detection sensors

Exit saturation sensor

Continuous or step-by-step flow

Specific workpiece carriers designed for the parts are provided with the parts washer. This type of conveyor allows :

Robot friendly configuration

Optimal part position for efficient cleaning and drying

The continuous flow cleaning of parts enables the highest production rates to be met, such as in the automotive industry.

Tunnel length according to the required throughput and processing time

Multiple parallel conveying lines.

As part of a stand-alone tunnel, a conveying loop equipped with crossovers allows loading and unloading stations to be combined at the same position.

Gravity roller conveyors

Operator control panels

Each module has a cover with a safety switch for optimum accessibility during maintenance operations.

Large covers above the tanks allow quick access to the filters.

Based on our know-how in the treatment of complex parts, MecanoLav has developed specific devices embedded in the cleaning tunnel for a targeted mechanical action.

Internal cleaning of railway bearing cage

Cleaning of small circuits by syringing with particle size requirements

MecanoLav’s DNA focuses on tailoring our machines to our customers’ cleaning needs.

This gigantic tunnel, more than 18 meters long and 8 meters wide, which is able to clean more than 400 different parts, is the perfect illustration.