3 sizes according to parts / components dimension

Automatic cycle with closed circuit

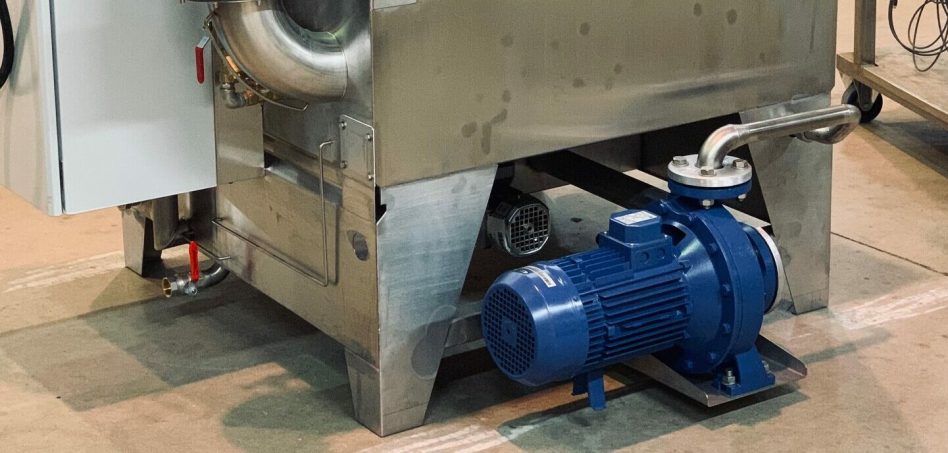

304L Stainless steel structure for strength and durability

Perfectly suited for maintenance of very dirty parts

Low energy and detergent consumption

Wide range of features to suit your requirements

Made in France

The ECO mechanical parts degreasing unit is divided into a range of 3 standard sizes according to the dimension, weight and quantity of parts to be cleaned.

IC2 > Ø780 mm – H450 mm – 150 kg max

IC3 > Ø900 mm – H 550 mm – 300 kg max

IC4 > Ø1100 mm – H 700 mm – 500 kg max

As a historical product of the MecanoLav range, its robustness is proven in many truck garages and maintenance workshops.

Maximum load capacity of 500 kg

Wide angle opening for hoist loading

Removal of dried grease and oil by high flow cleaning

Every step of the cleaning cycle are carried out fully automatically according to pre-set timers.

On request, the cycle can also include fully automated drying of the parts.

Time saving

Hidden time operations during cleaning

Consistent cleaning quality

The cleaning fluid is used in a closed circuit and filtered on several levels in order to collect pollution and protect the pump.

Low water consumption

Low detergent consumption

Drain frequency according to amount of pollution

In addition to automatic mode, ECO parts washer can include a hand operation mode to clean difficult areas for the most complex parts.

Glove pockets

Fluid spray gun operated with footswitch

Mode selection from the control panel

Glass sight and lighting with steam extractor

Before dye penetration or painting, optimal and repeatable rinsing after the cleaning step is necessary. For those application, ECO parts washer includes an additional module to rinse the parts by supplying fresh water.

Rinsing step with calibrated nozzles

Storage of rinse water in a buffer tank

Stability of the cleaning fluid concentration

Rinse water evacuation

A wide range of additional equipment can be included regarding the application, from process requirements to maintenance friendly features.

Disk or coalescing oil skimmer

Hot air drying and/or blowing steps

Steam extraction or condenser

Automatic filling with draining feature

Fine filtration