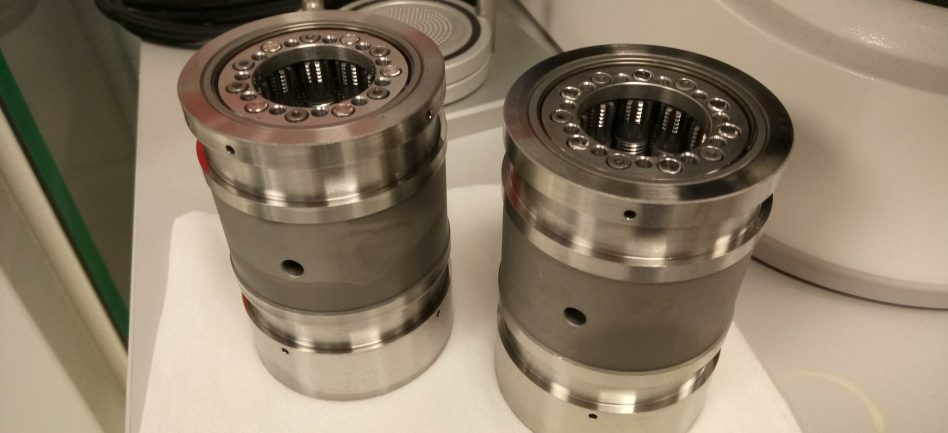

A well-known manufacturer in the general industry has sought our expertise in in-process roller screw cleaning.

Parts should be cleaned one by one in a continuous flow in less than 90 seconds.

Wide range of parts reference ->

Contamination -> cutting oil, grease, lapping paste and chips

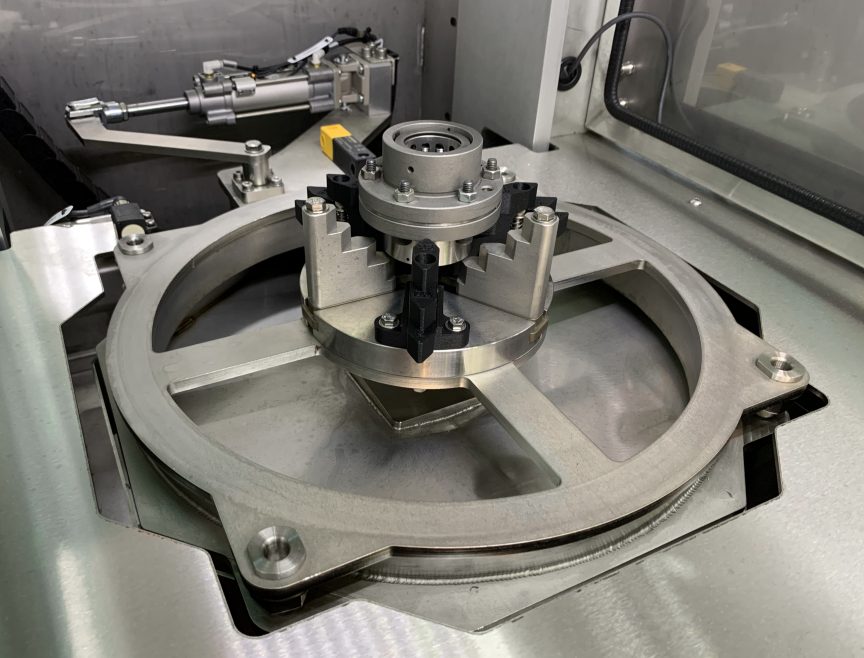

ID / OD cleaning according to the following criteria :

The parts are loaded by a technician on a custom-made workpiece carrier. The part clamp automatically.

Clean and dry in 90 seconds

Cleanliness requirement met

Optimized Takt time – no buffer