Swedish and French manufacturers in the general industry have requested our know-how for hydraulic cylinder body cleaning after machining and welding in final washing process.

Cleaning characteristic :

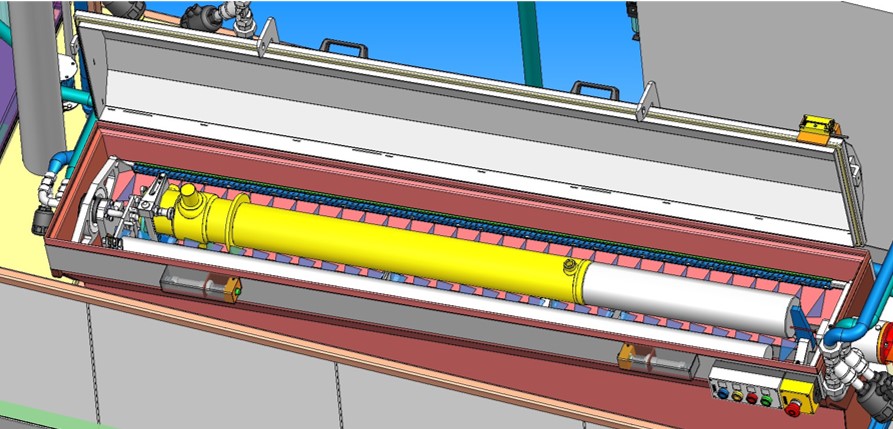

Maximal diameter: 7 1/16” (180 mm)

Maximal length: 6′ 13/16” (1850 mm)

Contamination -> cutting oil, chips, particles.

Outside diameter cleanliness requirements: degreasing and perfectly dry

Parts must be cleaned one by one in a continuous flow between 80 to 120 seconds.

Loaded with a hoist, the parts are manually loaded horizontally in the working chamber. The tooling can be adjusted in height to accept the different body diameters.

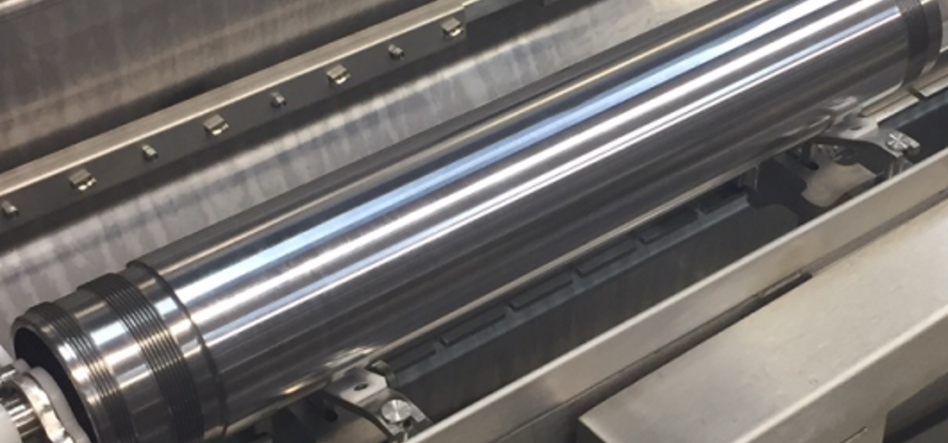

An electric cylinder operated a syringe to clean the ID of the body cylinder. The stroke is automatically adjusted according to the PLC program selected. A rotating cleaning tool ensures the outside diameter degreasing.

For an increased bath life, an oil skimmer separates the oils.