Ensure the degreasing quality before heat treatment process

Cleaning solutions adapted for maintenance and overhaul

Master all types of cleaning medias: chlorinated solvent, detergent, hydrocarbon solvent

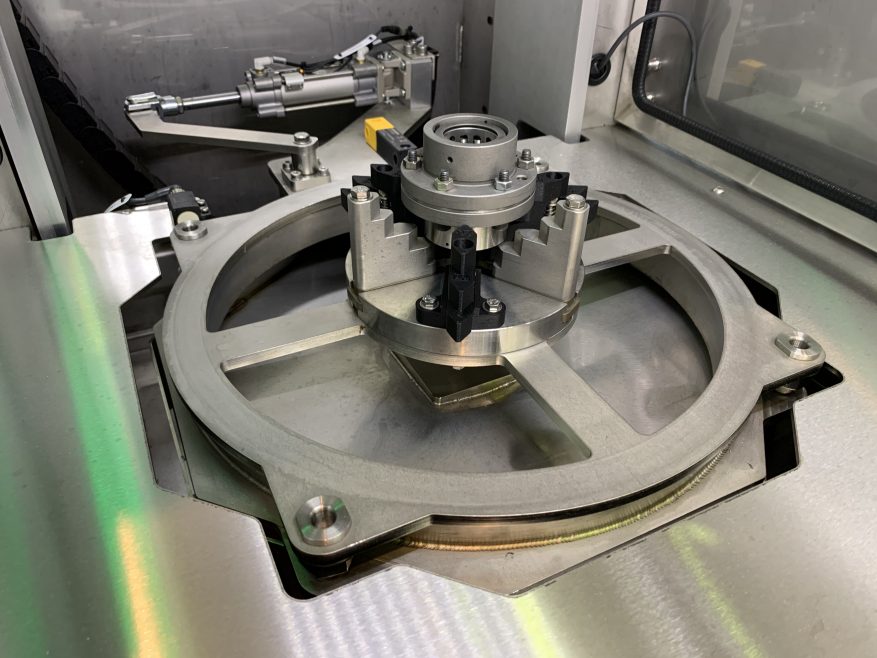

Guarantee specific cleanliness level for gravimetry and particle size

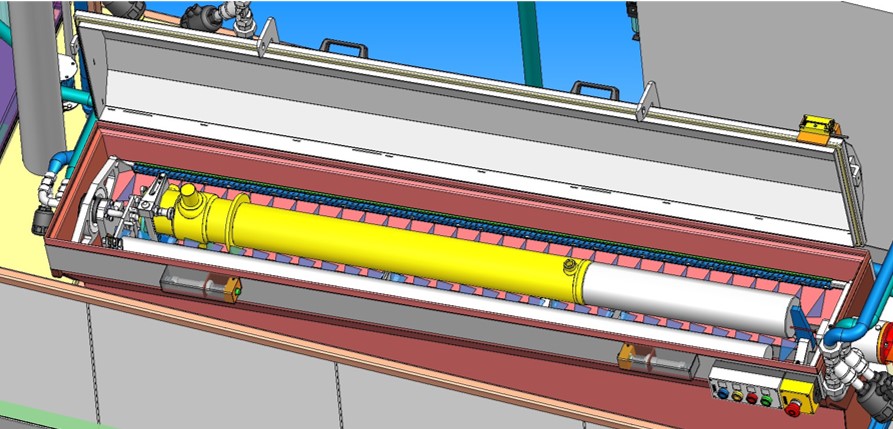

Provide a specific response for tubes & pipes cleaning

Our equipments ensure a cleaning process for your mechanical parts depending on your application and upstream/downstream operation :

Before heat treatment

Before surface treatment

Before dimensional check

Before coating / painting

In-process cleaning

Final Wash

The main objective of degreasing before TTH is to remove from the parts all contamination that could cause homogeneity defects in the treatment, and also to avoid pollution of the furnaces.

Various different issues are found: stored parts, bulk parts, parts with different geometries and materials with a long list of contamination that is not always well known. MecanoLav support you to find the appopriate cleaning solution.

Tough and dry contamination are representative of mechanical parts in the rebuild and maintenance field.

MecanoLav has more than 35 years of know-how with heavy tractor trailer, light vehicle overhaul, handling machine and nautical equipment. The product line ECO, MAXIMA and MB are design to accept large and heavy parts up to several tons.

To prevent mechanical blockage and rapid wear on precision components such as the roller screws, a proper final wash is necessary to meet all the cleanliness requirements in term of gravimetry (<2mg) and particle size (200µm)

The MecanoFAST process with his short cycle time, the POWERJET using ultrasound or the SOLVACS operating with vacuum solvents; Each of these system have the capacity to ensure the decontamination of the parts according to their complexity.

Cleaning the inside of the tubes, whether they are curved or straight, requires intense mechanical action by flushing or via a mechanized syringe tool to effectively remove particles and pollution from the surface.