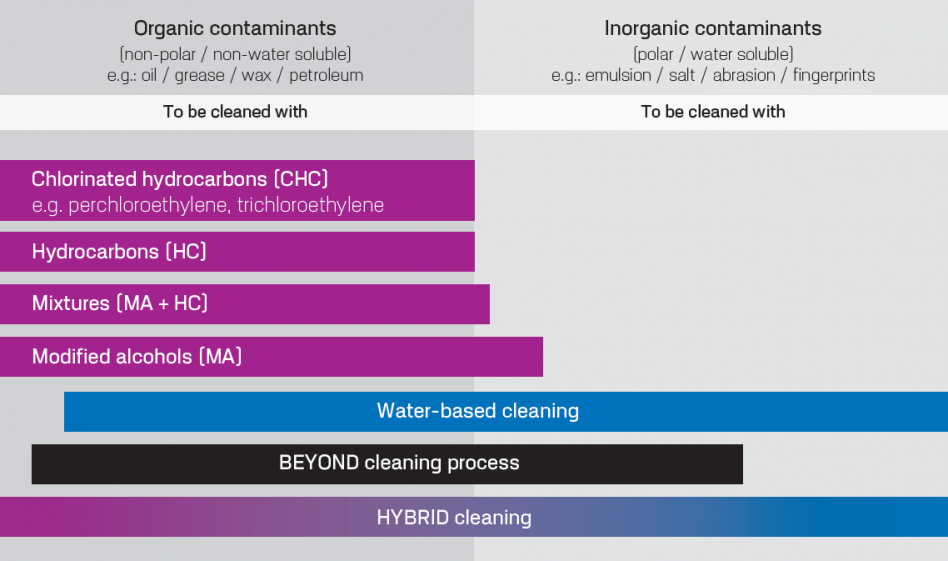

Use Modified Alcohols, Hydrocarbons A3 and Perchlorethylene

Hybrid Process > combination of aqueous solution and solvents

Works entirely under vacuum even in immersion phase

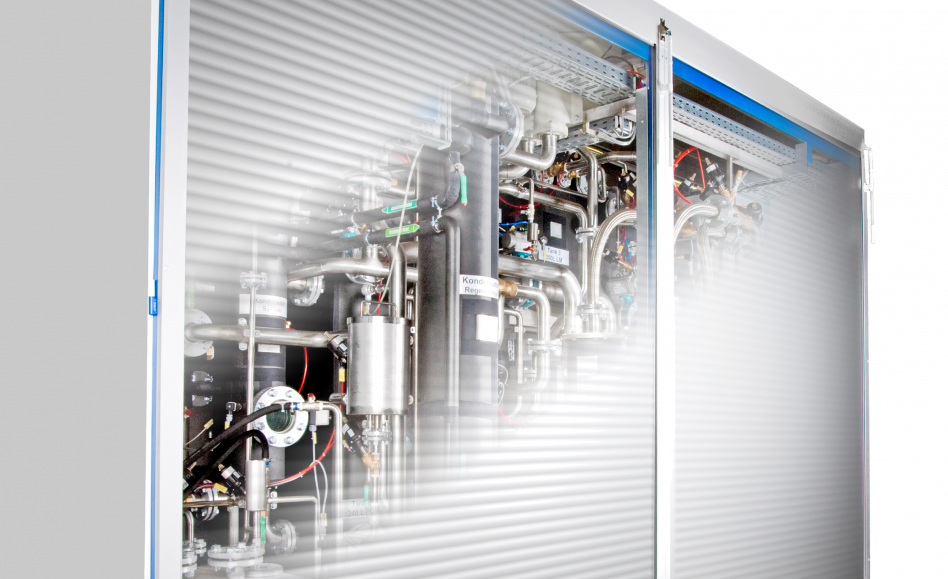

Distillation for continuous solvent regeneration

Immersion cleaning up to 203°F (95°C) and steam-phase degreasing

Closed-circuit work, no effluent discharge

Manufactured by our partner HEMO GmbH (EMO-HÖSEL merger)

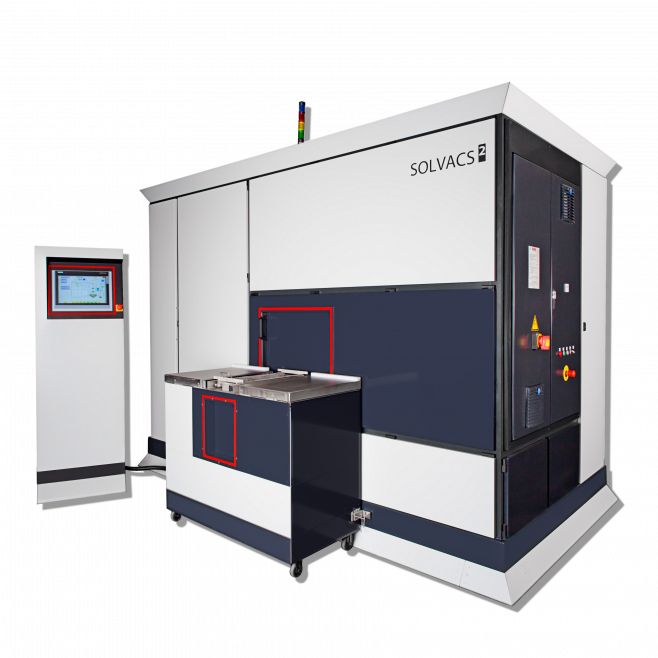

Abbreviation of SOLvent VACuum System , the SOLVACS vacuum degreasing machine meets the highest requirements for marks free cleaning / degreasing and drying performance.

Chamber heating by steam

Immersion degreasing up to 203°F (95°C)

Ultrasons and active immersion simultaneously

Steam phase degreasing

Anti-corrosion protection by immersion

Intensive vacuum drying

The entire system in contact with the solvent (<100 mbar) works under vacuum to make it possible to clean at a temperature above the flash point of the solvent in both immersion and steam phase.

For 3-shift operation, the machine incorporates a thermal cooling exchanger by a secondary circuit to increase cooling capacity.

The TWIN SAFETY GUARD system performs continuous monitoring of solvent flashpoint and the vacuum level via a dual safety (hardware and program).

Indirect heating of the solvent

Draining and automatic drying filters

Monitoring all valves and check valves

Condensation of air discharges to reduce solvent emissions

Floor tank with sensor

The SOLVACS vacuum degreasing machine is available in 5 different sizes, depending on the dimensions and the volume of the parts to be processed.

For special applications, the work chamber can be custom-made.

More than a degreasing machine, SOLVACS incorporates continuous distillation of the solvent to ensure optimal life and repeatable results.

In addition to that, an additional distillation minimizes the solvent content (<10%) in the waste being discharged.

Water and other substances are automatically removed at low boiling temperatures by the desaturation process.

The SOLVACS Hybrid provides marks free cleanliness by combining the action of solvent and aqueous solution to remove organic and mineral dirt.

This is particularly the case for vacuum deposits processing operations (plasma, nitration, etc.).

This system eliminates all types of organic and non-organic contaminations, with total compatibility of materials from the parts to be processed.

HEMO GmbH as the inventor of the technology has complete control of the process.

Automatisation of each process steps

High level of equipment as standard

TRIPLE filtration system

Filling and draining the work chamber by fine filtration

By-pass filtration

Tanks, condensers and pipes welded under inert gas

Manual loading > manual transfer of the load to the work chamber from a table 1 or 3 positions.

Automatic loading > transferred from a roller conveyor, the load is lifted and loaded automatically into the machine chamber.

At the start of the cycle the door is closed and locked automatically.

In order to offer a local service and a machine in perfect operational condition, the monitoring and maintenance of SOLVACS machines are carried out by the Surface Alliance after-sales service and partner.

Supports & Diagnostics

Remote maintenance via modem

Annual inspection of the equipment

HEMO GmbH is one of the founder of Surface Alliance, in 2017 EMO Oberflächentechnik GmbH and Hösel GmbH, two long-term partner companies from Bretten-Gölshausen and Ötisheim, merged to become HEMO GmbH.