4 to 6 loads per hour

Drum oscillation or rotation

Modular cycle : washing, rinsing, drying

Customized drum according to the load size

Integration of automatic loader, conveyors or gantry system

Customized drum according to the load size

Made in France

The MecanoJET is specialised for medium and large load allowing a processing capacity from four to six loads per hour.

Achieves high cleanliness requirements

Great flexibility

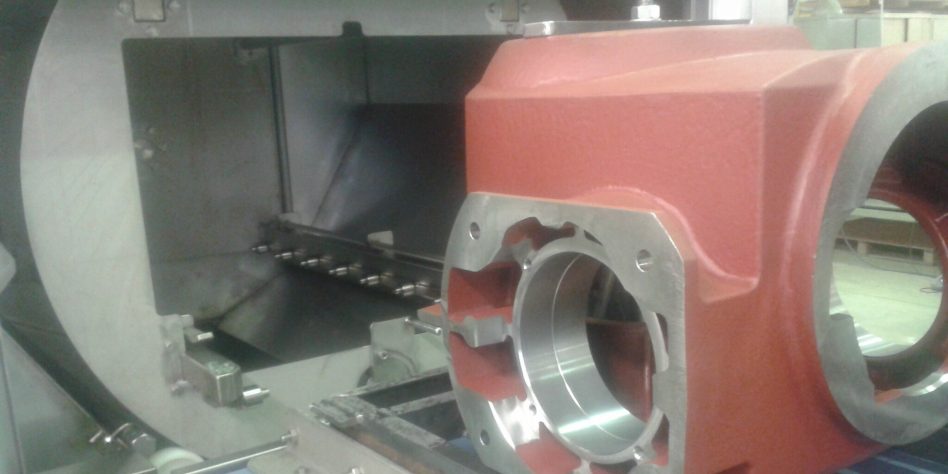

The MecanoJET can process loads from 670 x 480 x 300 mm (26 3/8″ x 18 7/8″ x 11 13/16″) up to a custom-made drum.

Her twin sister, the MecanoJET Compact can process baskets or palets with dimensions up to 530 x 320 x 200 mm (20 7/8″ x 12 5/8″ x 7 7/8″).

For each cycle, the MecanoJET has the possibility to select between full rotation or drum oscillation.

Full rotation > closed basket / non-sensitive parts or clamped in position

Oscillation with a set angle > workpiece carriers / sensible parts

All devices and features are integrated in the MecanoJET maintenance area. Its strong frame including forklift pockets allowseasy installation on the production workshop.

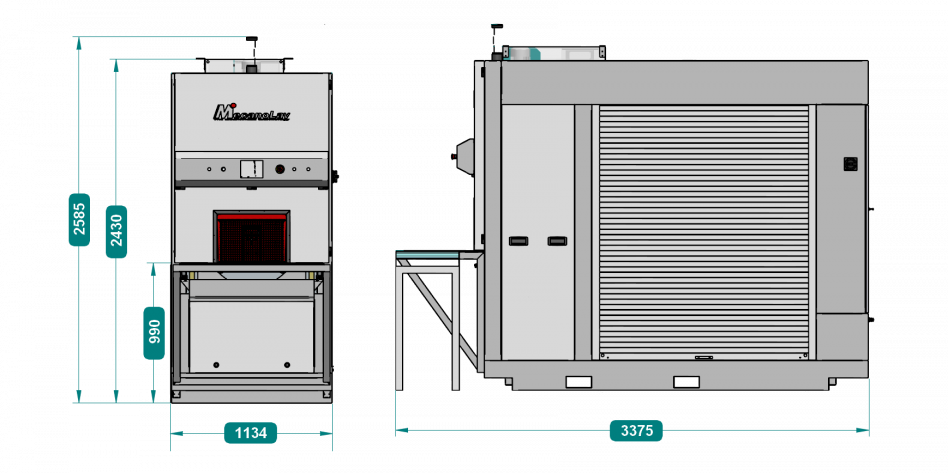

Width 1130 mm (3′ 8 1/2″)

Easy installation in a production cell

Optimal accessibility via two side rollers shutters

To achieve great degreasing performances, the MecanoJET is equipped with two separated tanks.

The cleaning cycle can be adjusted depending on cleanliness requirement and the parts to be cleaned.

Spray washing step

Spray rinse step

Hot air drying and/or blowing step

In complementary of the standard mesh baskets or bins, the MecanoJET allows to process parts stored on customized pallets.

MecanoLav provides CAD design internally as well as the manufacturing of these specific tools.

To simplify the loading/unloading process flow, additional devices are simply integrated on the degreasing equipment.

Automatic loader with machine PLC communication

Automatic lifting and locking in place by lifting table

Upstream / downstream conveyors

3 positions manual table to load/unload parts in hidden time

The MecanJET is equipped with a touch screen interface allowing a user friendly utilization for technician.

Cleaning cycle settings

Process parameters visualization

Parameters modification

Machine alerts and faults management

Traceability with cleaning report edition

The MecanoJET is a through hole version (tunnel type entrance and exit)

Using the tunnel flow principal, the rotation / oscillation insure a great machine performance in term of facilitating the drying process on the part to be treated.