Fast > high production flow (cleaning and drying in a few seconds)

Ultra Compact

Efficient > Meets cleanliness standards (gravimetry – particle size)

Polyvalent > manual or automatic loading

One piece flow cleaning process without buffer

Lean manufacturing solution

Made in France

MecanoFAST 250 ensures a very high cleaning rate, with cleaning and drying cycles between 20 and 60 seconds, depending on the workpiece type and complexity.

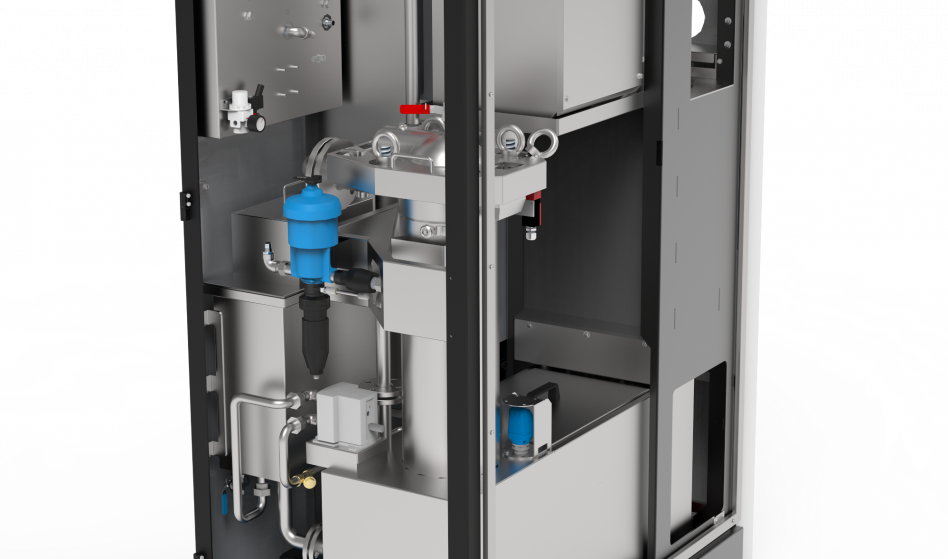

The MecanoFAST 250 is ultra compact, it can be easily integrated inside the production line and brings closer the upstream and downstream operations.

Your workpiece exceeds these dimensions ?

The batch/basket cleaning concept generates a major disruption for the production efficiency resulting in slowing down the flow and generating downstream and upstream stock.

The MecanoFAST process takes a very different approach, this equipment use the one-piece flow concept with a short cycle time.

Loading / unloading on the same fixture

Single piece > no buffer

Quick machine fault detection during cycle

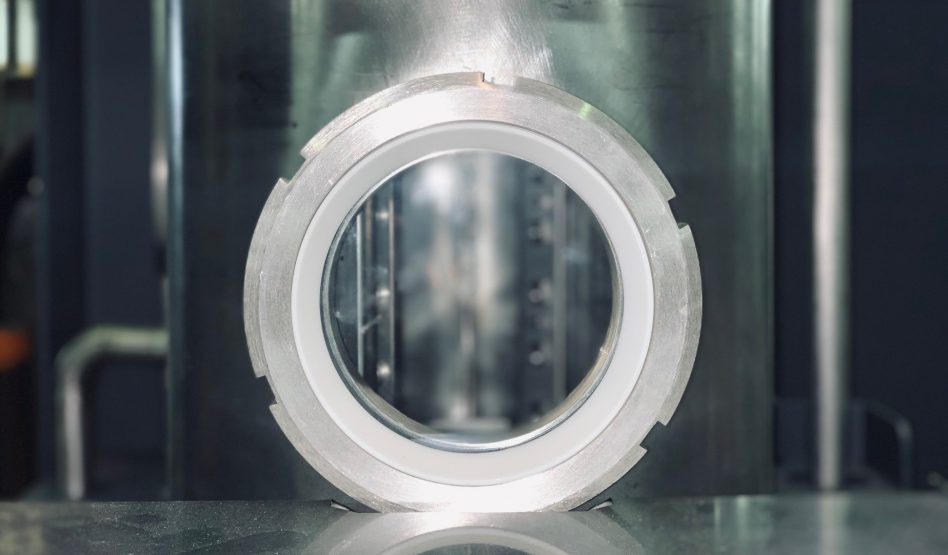

MecanoFAST patented technology is based on a dedicated part cleaning, considering its geometry and complex shapes.

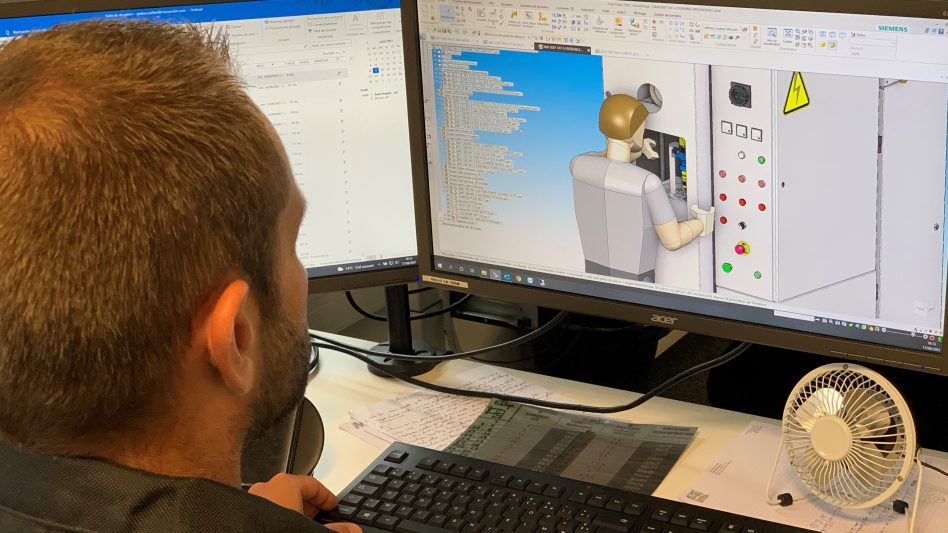

We support you by setting up validation trials and analysis in our laboratory, according to the standards VDA19 – ISO 16232.

Depending on the use condition, the machine can be produced in 2 versions.

The MecanoFAST 250 is consuming 2 times less energy and uses 4 times less water than a traditional system such as Tunnel ou Carrousel process.

Quick change over in less than 2 minutes

Reconfigurable : only part fixture and tools need to change/redesign

The machine is equipped with sliding doors to ensure a secured and simplified access to the filtration system, tank and other moving parts.