6 standard sizes to suit your parts dimensions

Large capacity work chamber for large loads

Front loading with tilt door or trolley

Useful dimensions adjustable as needed

Closed circuit operation

304L Stainless steel structure for strength and durability

Degreasing of mechanical parts in a few minutes

Made in France

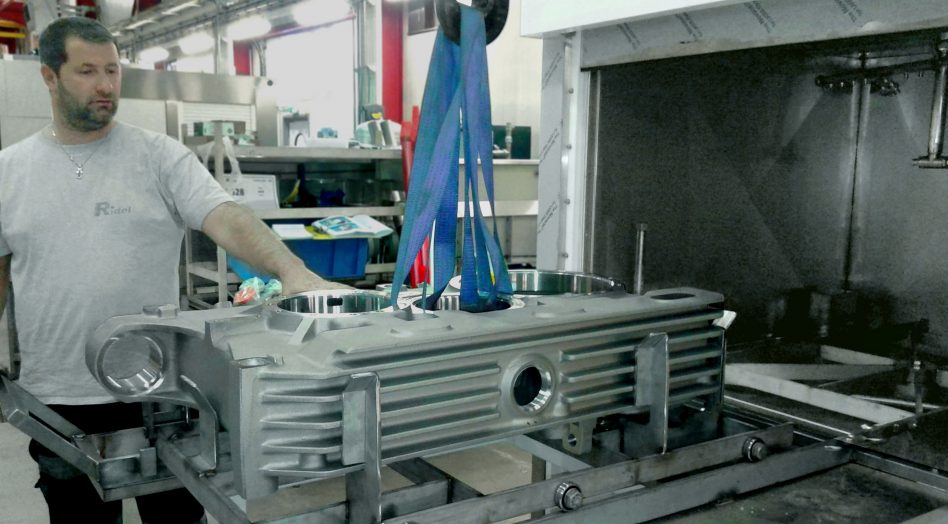

The MAXIMA mechanical parts degreasing machine is divided into a range of 6 standard sizes according to the dimensions, weight and quantity of parts to be cleaned.

MAXIMA 8 > L800 x W800 x H800 mm

MAXIMA 10 > L1000 x W1000 x H800 mm

MAXIMA 13 > L1300 x W1300 x H800 mm

MAXIMA 15 > L1500 x W1500 x H800 mm

MAXIMA 18 > L1800 x W1800 x H800 mm

MAXIMA 20 > L2000 x W2000 x H800 mm

Historic product of our product line, the MAXIMA has proven its robustness in many truck and railway maintenance workshops.

Load capacity up to 2 tons

Removal of dried grease and oil by high flow spraying

With its closed circuit tank, the MAXIMA cleaning and drying stages are carried out automatically after the operator starts the cycle.

The MAXIMA is available with multiple tanks > MB product line

Significant time saving

Low energy consumption

Repeatable cleaning quality

MAXIMA front loading feature is available in two versions :

If large quantities of pollution are present and quickly saturate the tank (grease, sludge, oil, resins), the machine incorporates reprocessing devices to isolate this pollution in order to space out emptying and guarantee the cleaning performance.

Oil skimmer

Degreaser – decanter – scraper dredge

Scrolling paper filter

In accordance with the dimensions of the parts to be cleaned, the cleaning unit can be adapted and equipped in consequence.

Custom-made work chamber

Useful height up to 2000 mm

Change of the door by a motorized roller shutter

In-pit machine

The MAXIMA can be equipped with a hand operation mode to clean difficult areas for the most complex parts.

Glove pockets with safety switch

Fluid spray nozzle

3-way valve to change between operating modes

Glass sight and lighting with steam extractor

Cleaning complex and sensitive parts in the aeronautics industry requires that the cleaning fluid be the fuel that will be used in the circuits (kerosene, MEK, Diestone, etc.).

MecanoLav has a unique know-how for the manufacture of cleaning machines operating in explosive atmospheres (ATEX).