8 to 16 cleaning steps depending on production flow and cleaning process

Complete cycle in closed circuit: washing, rinsing, drying

High production rate

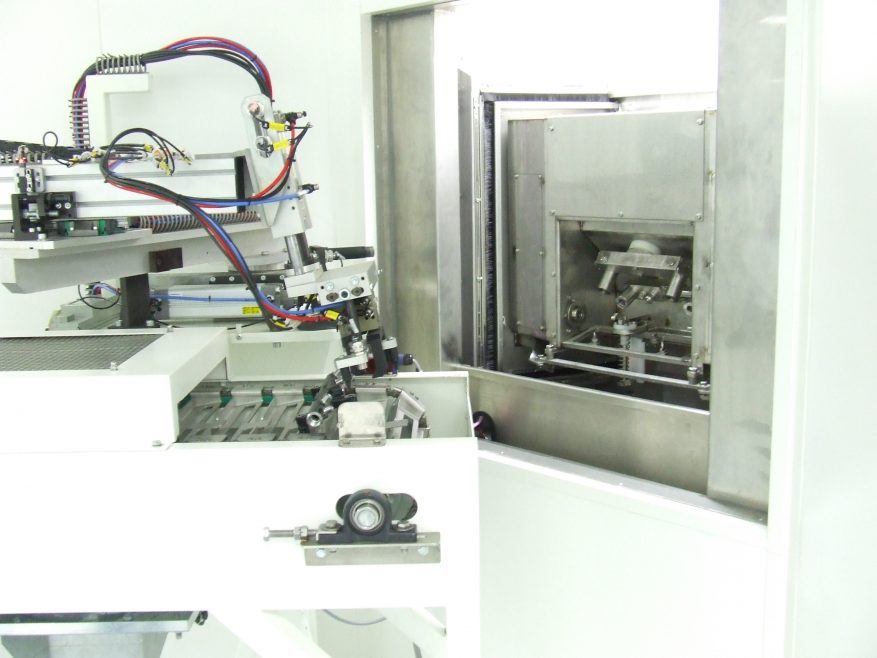

Precise indexing for robotic loading

CAD design and manufacturing of Workpiece carrier

Cleanliness standards | gravimetry – particle size

Useful dimensions can be adapted as needed

Made in France

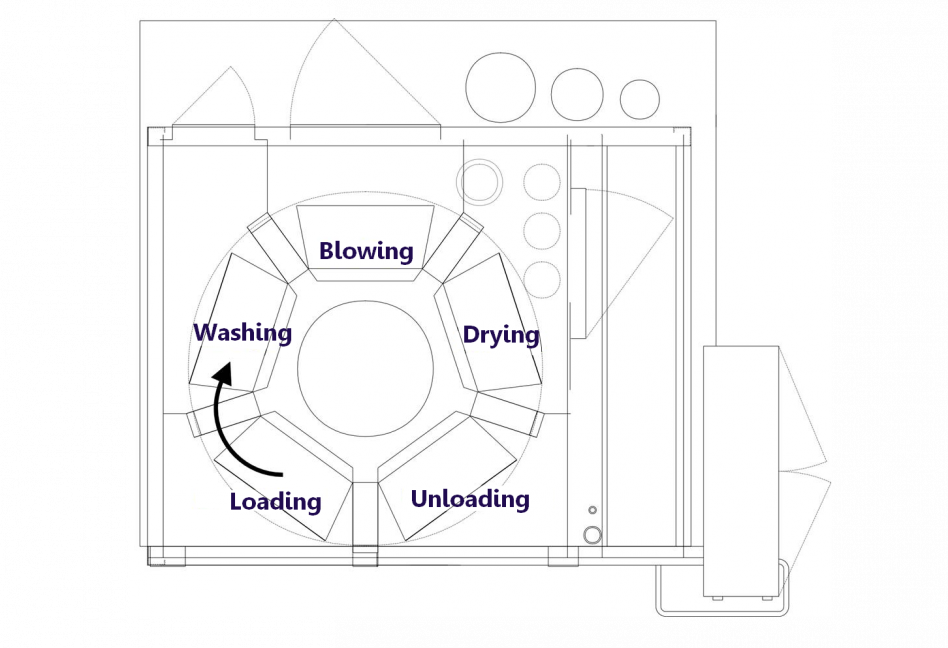

Carousel is based on the principle of a barrel.

The indexed step-by-step rotation performs successive cleaning / drying phases in separated modules.

Quantity of steps, rotation speed and treatment time in each station enables the system to meet your cleanliness requirements and production flow.

En deux postes dédiés ou sur un seul et même poste, le chargement et le déchargement du Carrousel peut être réalisé manuellement ou par un robot.

Loading and unloading of the carousel can be done manually or by a robot, either at two dedicated stations or at one location.

Loading and unloading at the same station

Operator access protected by light curtains

A stable position is required to allow robotic loading.

The workpiece carrier is designed by our engineering department according to the part diversity to ensure an efficient cleaning and drying.

The environment of the machine is a key factor in achieving cleanliness requirements on complex and sensitive parts.

For this purpose, the carousel can be integrated into a clean room to meet the most stringent cleanliness standards.

Except for a very rare exception, applications where Carousel was the privileged cleaning solution are now focused on a new innovative parts wasger that erases its historical weaknesses: the MecanoFAST.

Fast > High production rate (few seconds)

Compact > Under 2m² / 22 ft² floor space

Efficient > Meets to cleanliness standards | ISO 16232 – VDA 19

Robot friendly > Robot cell cleaning

One piece flow cleaning process without buffer