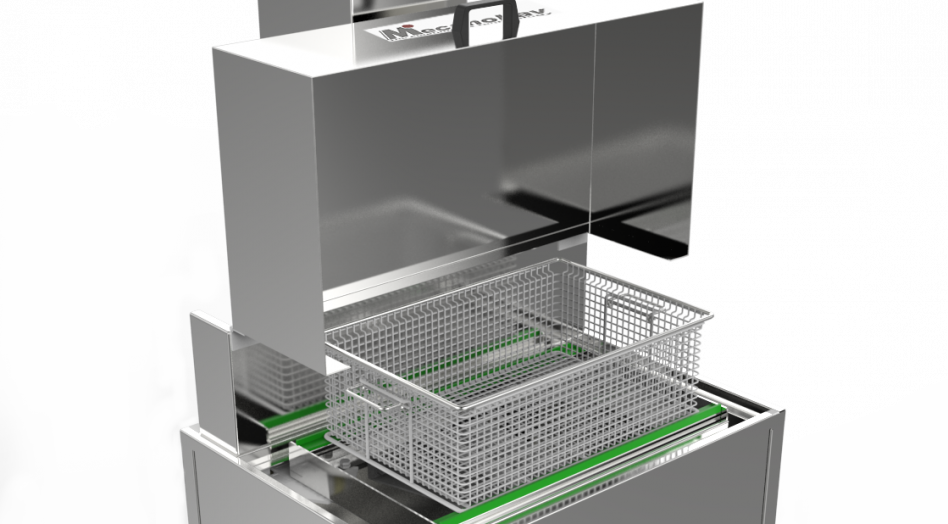

Immersion and agitation cleaning process

304L Stainless steel structure

Useful dimensions can be adapted as needed

Heating feature according to application

Front loading with vertical door and steam extraction

Additionnal equipment according to application

Made in France

In addition to the standard size, the AgiLav is also available in tailor-made sizes to suit the basket or parts to be cleaned.

Useful dimensions: 600 x 400 x 200 mm

Maximum load: 40 kg

Customised useful dimensions

Except when the AgiLav is designed to apply a protection agent (rust protection, passivation…), it is equipped with a heating device to ensure degreasing of the parts and ambiant air drying at the end of the cycle.

Protection agent

Heated cleaning fluid

Electrical heater can”t be damaged by lack of water

The parts are clean by immersion in a stainless steel wire basket.

A lifting device is used to agitate the basket in the cleaning fluid.

Automated management of the agitation frequency

Robust lift guidance system.

To enable baskets to be carried to upstream and downstream conveyors, the lifting device completely extracts the basket from the cleaning tank.

Raised lid with safety switch

Easy batch transfer by using anti-friction guides

Full basket extraction

As an additional equipment, the AgiLav can integrate a work chamber above the cleaning tank in order to freely transfer the basket from the loading station.

Automatic opening vertical door

Steam extraction

Loading station with transfer rollers