A well-known manufacturer in the general industry has sought our expertise in worm shaft cleaning in inter-operation.

Parts must to be cleaned in continuous cycle in less than 90 seconds.

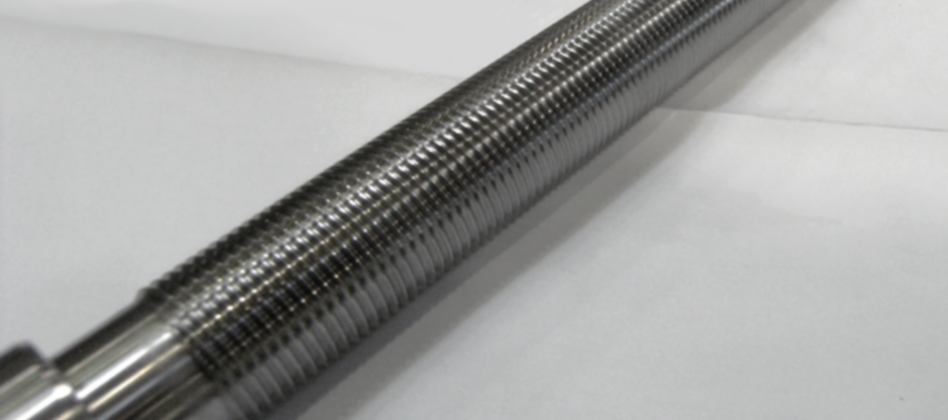

Large amount of references : diameter from 8 to 100 mm and length from 150 to 1700 mm

Contamination : cutting oil, grease, lapping paste and chips

ID/OD cleanliness according to the following criterias :

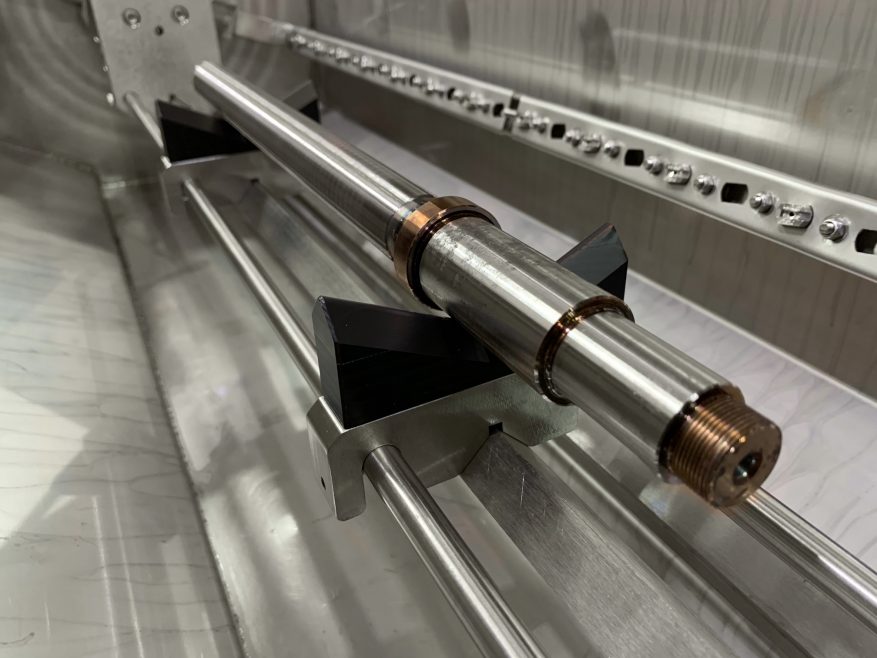

The parts are loaded horizontally by a technician on V-block fixture or in custom-made clamp rings.

Before the cycle start, the technician manually closes the lid of the working chamber in which a specific washing, rinse and drying tool performs a defined cleaning cycle on the part.

Clean and dry in 90 seconds

Cleanliness requirements achieves in-process and final washing

Optimized take time – no buffer