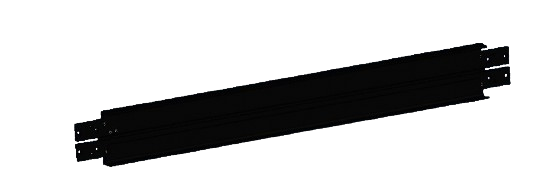

A German company specialising in electrical and pneumatic transmission components asked MecanoLav to wash machined profiles.

Our project was based on the internal and external cleaning of 11 references of long parts. Our aim was to achieve the required cleanliness prior to a lacquering operation.

The machine, with its inclined horizontal work chamber, can accommodate up to 11 part numbers simultaneously.

The cover of the machine is hinged, with manual opening assisted by gas struts and secured by an electromagnetic lock.

The parts support is mobile, providing easy access for loading and unloading operations.

The design allows easy handling of the parts while ensuring safety thanks to an electromagnetic locking mechanism.

Thanks to the mobile support system, operators can load and unload parts efficiently and safely.

Each reference requires 495 seconds for complete cleaning.

The repeatability of degreasing results before painting is ensured by the use of two separate baths.

The machine uses a rotating device to clean the external surfaces of the parts.

Targeted nozzles are used to clean the inside of the parts, guaranteeing optimum efficiency.