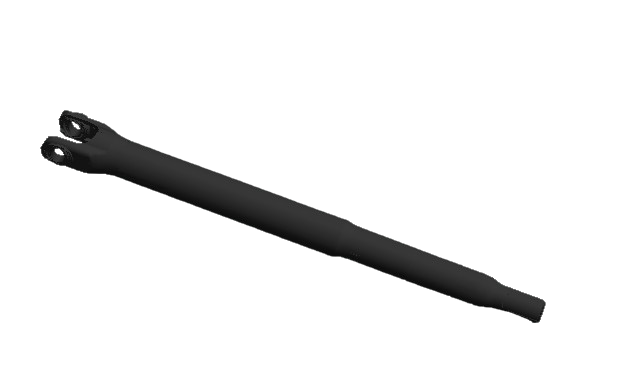

An automotive supplier called on MecanoLav’s expertise to design and supply a cleaning machine for steering column shafts.

The aim of the project was to achieve a cleaning cycle time of 12 seconds per part, while guaranteeing precision on a variety of parts ranging from 120 to 420 mm.

The aim was also to facilitate integration of the machine into a robotized island, enabling smooth automation of the process.

The machine cleans 3 parts simultaneously, as 12 seconds per part.

Parts are deposited and retrieved in takt-time by a robot, using a 3-position rotary table for easy access.

The machine is equipped with fixture pallets that can be adapted to multiple part references (120 to 420 mm high).

The working chamber is optimized for precise part cleaning, ensuring internal and external action as close as possible to the shafts.

The machine is compact, making it easy to integrate into a robotic island (3400 mm x 1600 mm).

What’s more, the robot gripper has free access to the loading and unloading stations.