A company specialising in the aerospace sector called on MecanoLav’s expertise to design and supply a tube cleaning machine.

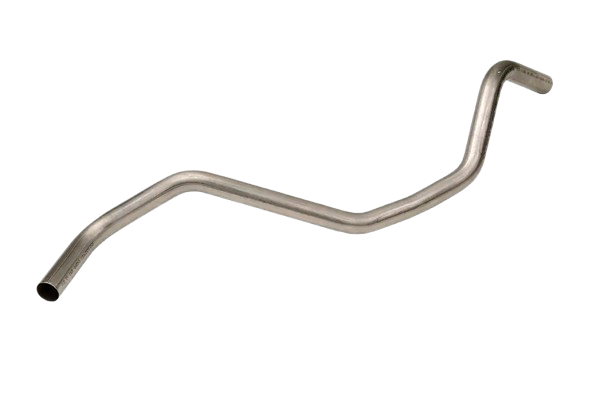

The aim of the project was to ensure the effective depollution of long tubes, guarantee cleanliness in line with the sector’s requirements and provide a controlled process to ensure perfect repeatability.

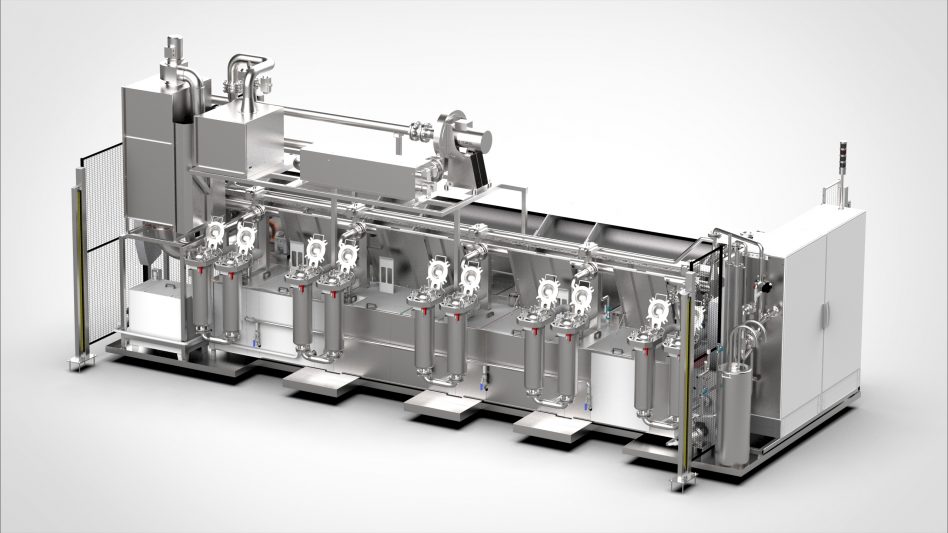

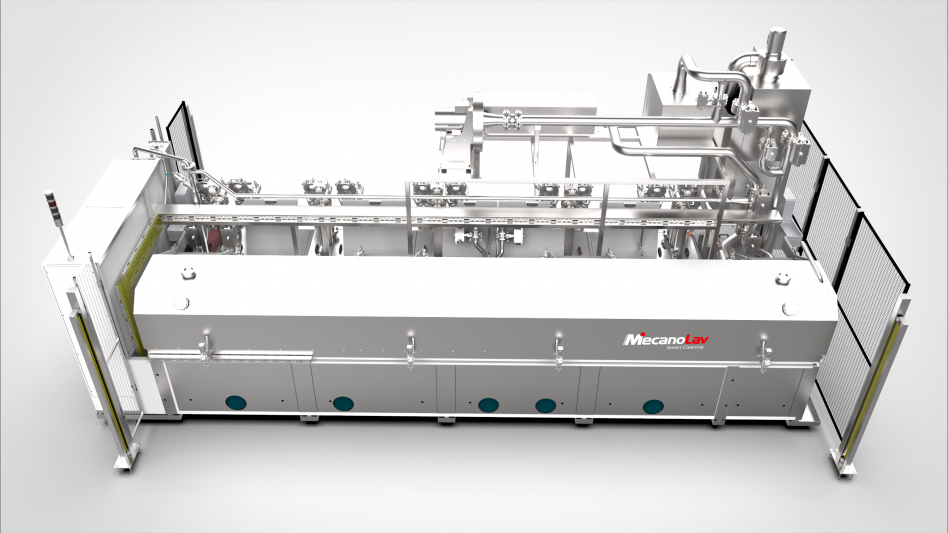

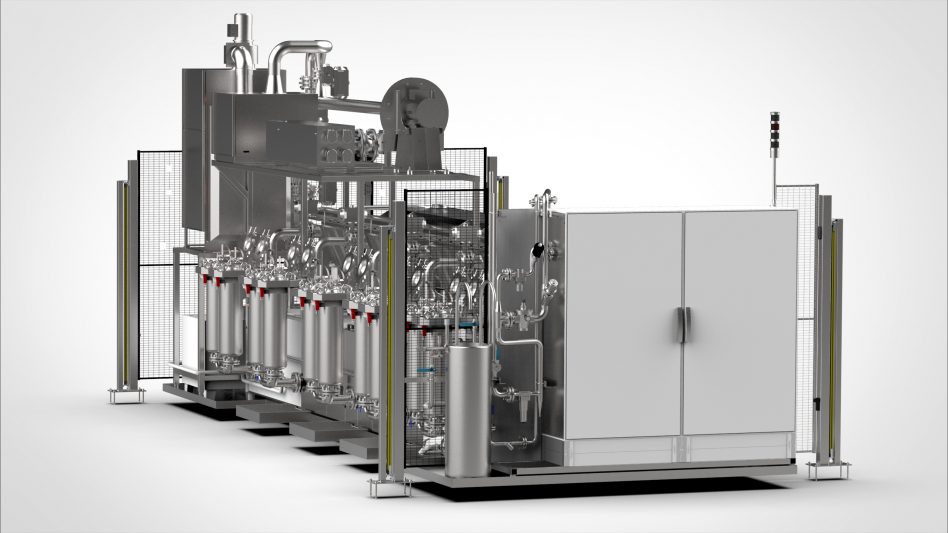

The machine has a horizontal chamber with a useful dimension of 6000 mm x 800 mm, which can accommodate tubes up to 6 metres long.

The spraying systems each include 100 conical nozzles and an internal flushing action to ensure uniform cleaning.

The cleaning process includes a washing tank and three rinsing tanks in a closed circuit, incorporating a resin in the last tank to guarantee stable conductivity of the osmosis water.

The installed drying device guarantees dry tubes at the end of the cycle.

The water and air circulation system has been designed to ensure repeatable performance with each cycle.