A company specializing in casting and machining called on MecanoLav’s expertise to design and supply a machine for cleaning EV battery cooling support.

The aim of the project was to ensure a cycle time of 150 seconds, and to guarantee an automated and safe process in a robot cell.

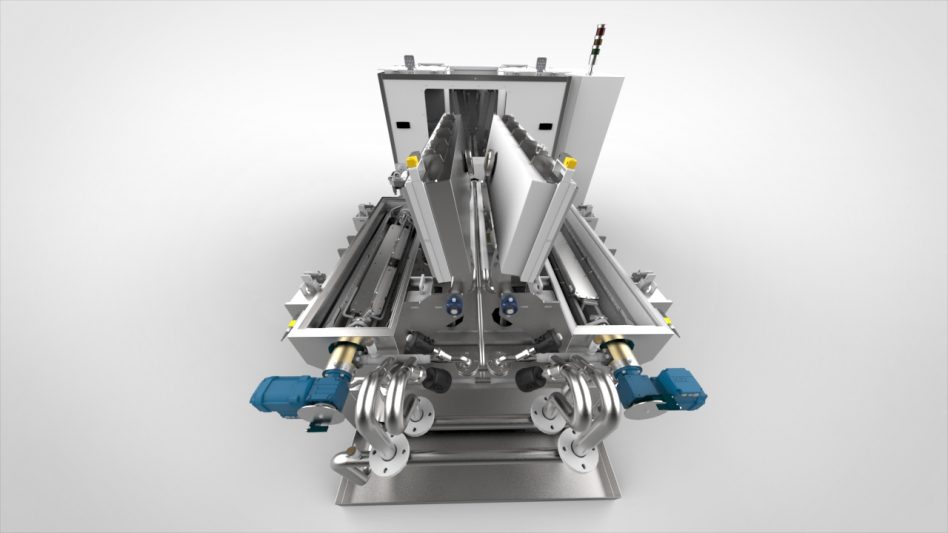

The machine cleans two different parts, each adapted to a specific reference.

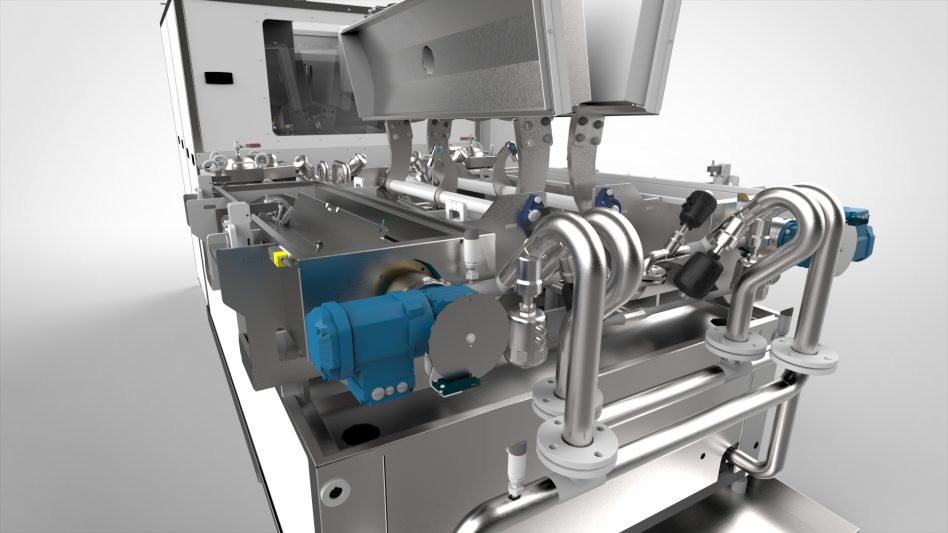

Cleaning, rinsing and drying take 150 seconds per part.

Cycles are automatic between the two chambers, thanks to pilot-operated valves that alternate process steps.

Easy, unobstructed access to the robot for part removal from above, via automatic hatch.

Process repeatability is ensured by precise part positioning and avoiding collisions during loading and unloading.