A company in the railway industry has requested our expertise in the railway axles cleaning, before repair and maintenance.

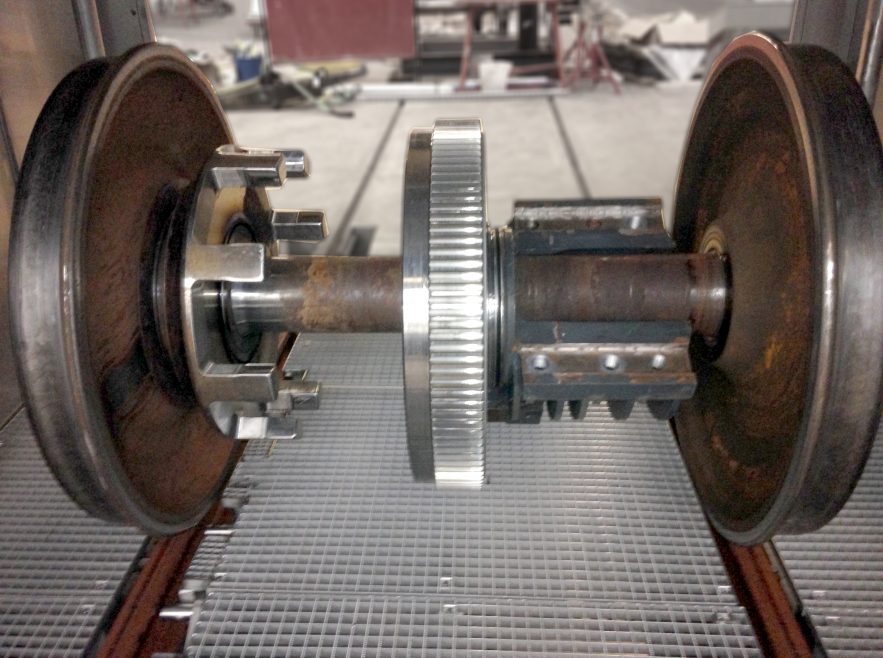

The machine can run up to 25 different railway axles assembly and single shaft.

Wheels diameter from 23 5/8” to 51 3/16” (600 à 1300 mm) with a 3 tonnes maximal load.

Contamination > grease, oil, sludge, dirt etc…

Results; contamination free and dry.

Speed rate : 1 railway axle every 30 minutes

The axles roll by moving through the MB25S machine to follow a continuous flow of production.

Long spraying ramps with some rotating sized nozzles will clean the axle from all sides.

In order to obtain repeatable results and an extended baths life, a dredge scrapes the sludge that settles in the bottom of the bath. A degreaser/decanter ensures the grease separation.