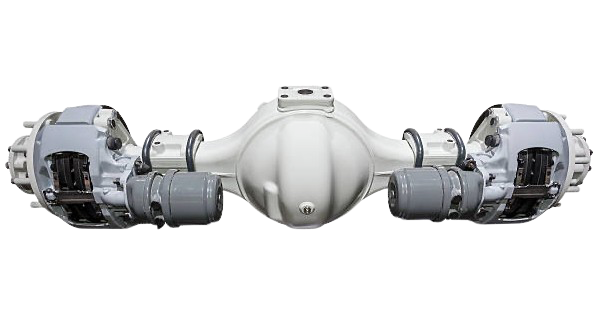

A manufacturer of cars and trucks called on MecanoLav’s expertise to design and supply a washing machine dedicated to cleaning electric rear axles.

The aim of the project was to efficiently remove particles larger than 1000 microns from parts with complex geometries, up to 2.30 meters in length. The solution also had to be fully automated and easily integrated into a robotized production cell, to ensure optimum continuity of the manufacturing process.

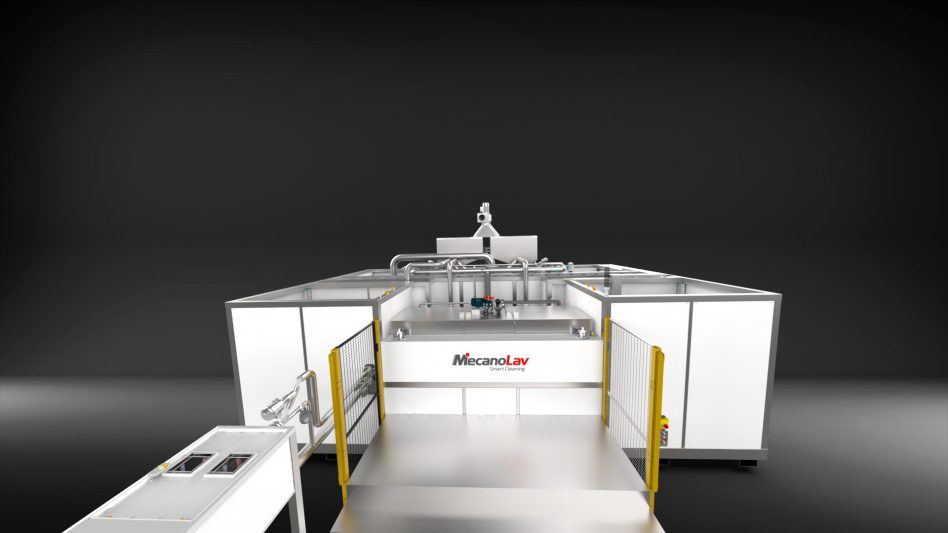

A 2.336-meter-long horizontal chamber has been specially designed to perfectly match the length of the room.

The custom-designed multi-spray system ensures complete coverage of internal and external surfaces, guaranteeing optimal cleaning.

The horizontal chamber is equipped with a 90° self-opening cover, allowing optimized robotic access for loading and unloading parts.

An intermediate module incorporates a high-capacity drum filter, designed to absorb large quantities of swarf, with centralized evacuation ensured by a dredge system.