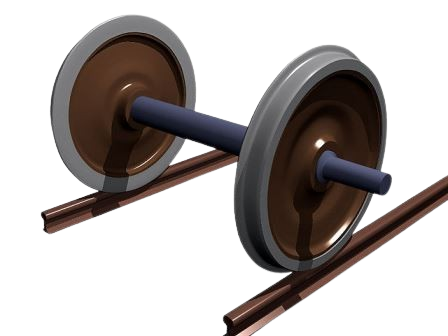

A French public railway company called on MecanoLav’s expertise to design and supply a machine for washing railway axles.

The project was based on degreasing massive parts measuring over 2.5 metres, while optimising the process through automation and the durability of the baths.

The machine’s useful dimensions are 2800x1500xH1800 mm, so it can handle parts up to 2.5 metres long.

It can degrease 40 axles in 7 hours.

It’s designed to accommodate workpieces up to 2.5 meters in length and support loads of up to 3 tons.

The baths are heated by a gas burner.

Oscillating and rotating ramps ensure a complete degreasing of each axle.

A system of mechanical stops ensures that the axles to be cleaned are securely locked, providing stability during the process.

The transfer of the axles is fully automated thanks to a mechanical system controlled by a PLC, allowing autonomous loading and unloading (through machine).